22 Products

-

-50%

-

Promotion

If you are buying a kit, you will probably already have a large proportion of screws and bolts, as well as pre-drilled holes.

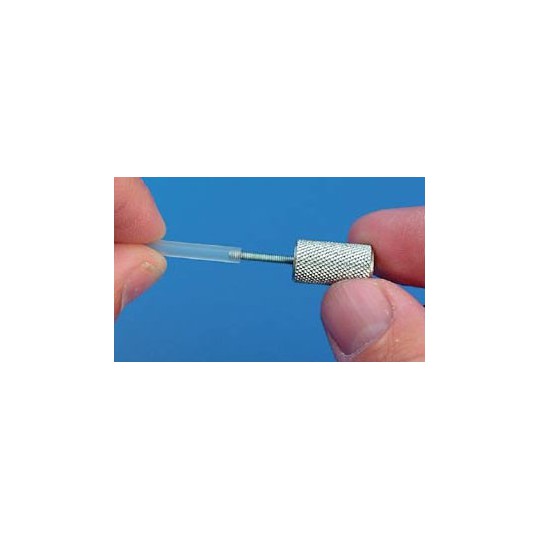

Bolts can come in variable lengths, but unlike screws, their diameter remains constant. Instead of a screw, which can be fixed into wood or plastic, a bolt is usually screwed into a harder material, like metal, and will not move. To insert a bolt into the piece of material without damaging it, you will need to thread a hole into it using a tap.

How to choose your tap ?

Taps come in different forms. They can be straight or helical. They are similar to drill bits, with the added feature of being able to create a threaded hole for your bolt. Depending on whether a tap has straight or helical grooves, the material will not be threaded in the same way, and the choice of one or the other will largely depend on the material you wish to tap.

If you need to use a tap to make a threaded hole, we would recommend having the drill bits and dies to match the taps you are going to use. The diameter of your drilled hole will depend on the diameter of the bolt that you wish to thread into it. You should also check that the thread of your taps and dies match. If you are using a right hand threaded tap, your die should also have a right-hand thread.

You have specific diameters for all your taps, as you do with all bolts. If you have a certain sized bolt, you can simply use the corresponding sized tap. But if you are starting from scratch and threading both the hole and the metal rod, you will simply have to work with a tap and a die that match each other, after having made a hole with a drill bit that is slightly smaller than your tap.

How do you maintain your tap ?

Like all tools, taps require some precautions when used. You can buy them individually or in sets. There are different types of taps, each corresponding to a specific stage of tapping: roughing, intermediate or finishing taps.

Before tapping, the hole must first be drilled to a specific diameter. For example, for a 3 mm tap, it will be necessary to pre-drill 2.5 mm hole. Careful not to drill a hole too small as this can damage your tap.

Tapping is usually done by hand, and it is advisable to do it in several steps. This is because the metal scraps produced when turning can clog up the hole and damage it. As tapping is a precise operation, we would recommend doing it by hand, using a tap wrench.